Online Continuous Monitoring System

Online Continuous Monitoring System

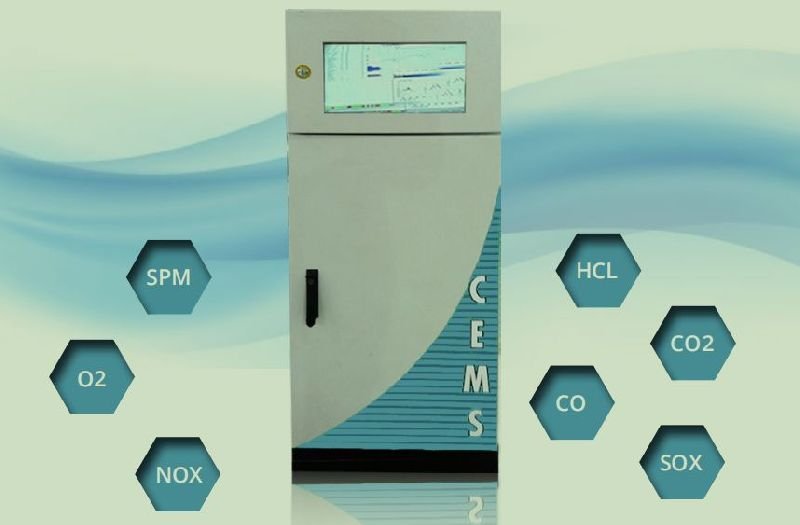

An online continuous monitoring system is one that continually monitors and collects data in real time from numerous sources. It is commonly used in areas including as manufacturing, energy, healthcare, and environmental monitoring, where important metrics must be constantly monitored.

The following are some major characteristics and components of an online continuous monitoring system:

Sensors and Data Acquisition: The system is comprised of sensors or data acquisition devices that collect information from the environment or equipment. Temperature, pressure, humidity, flow rate, voltage, current, and other characteristics can be measured by these sensors. The collected data is subsequently sent to the monitoring system.

Data Transmission: Using wired or wireless communication techniques, the gathered data is delivered to a central monitoring system. Ethernet, Wi-Fi, cellular networks, and specialised industrial protocols are examples.

Data Storage: A database or storage infrastructure is often included in a monitoring system to store the acquired data. Depending on the application’s needs, storage might take the shape of a local server or a cloud-based solution.

Real-Time Analysis: Data is analysed in real time to find any abnormalities, trends, or patterns. This analysis may employ statistical approaches, machine learning algorithms, or established rules to discover deviations from typical behaviour or provide warnings for abnormal circumstances.

Visualisation and Reporting: The monitoring system includes a user interface or dashboard that allows you to visualise the data that has been collected.

Notifications and alerts: If the monitoring system discovers any critical or abnormal circumstances based on the analysed data, it can issue alerts or notifications to notify the appropriate employees. These warnings can be issued by email, SMS, or linked with other channels of communication.

Historical Analysis and Trending: Historical analysis and trending of the monitored parameters are frequently included in the system. This enables users to examine historical data, detect long-term trends, and make informed decisions based on prior patterns.

Overall, an online continuous monitoring system allows for real-time data collecting, analysis, and visualisation, revealing information about the performance, efficiency, and safety of monitored processes or systems. It assists organisations in detecting and addressing issues quickly, optimising processes, and increasing overall productivity and dependability.

Data Transmission: Using wired or wireless communication techniques, the gathered data is delivered to a central monitoring system. Ethernet, Wi-Fi, cellular networks, and specialised industrial protocols are examples.

Data Storage: A database or storage infrastructure is often included in a monitoring system to store the acquired data. Depending on the application’s needs, storage might take the shape of a local server or a cloud-based solution.

Real-Time Analysis: Data is analysed in real time to find any abnormalities, trends, or patterns. This analysis may employ statistical approaches, machine learning algorithms, or established rules to discover deviations from typical behaviour or provide warnings for abnormal circumstances.

Visualisation and Reporting: The monitoring system includes a user interface or dashboard that allows you to visualise the data that has been collected.

Notifications and alerts: If the monitoring system discovers any critical or abnormal circumstances based on the analysed data, it can issue alerts or notifications to notify the appropriate employees. These warnings can be issued by email, SMS, or linked with other channels of communication.

Historical Analysis and Trending: Historical analysis and trending of the monitored parameters are frequently included in the system. This enables users to examine historical data, detect long-term trends, and make informed decisions based on prior patterns.

Overall, an online continuous monitoring system allows for real-time data collecting, analysis, and visualisation, revealing information about the performance, efficiency, and safety of monitored processes or systems. It assists organisations in detecting and addressing issues quickly, optimising processes, and increasing overall productivity and dependability.